Gupta Metal Mesh

Sumit Gupta

Owner

ABOUT US

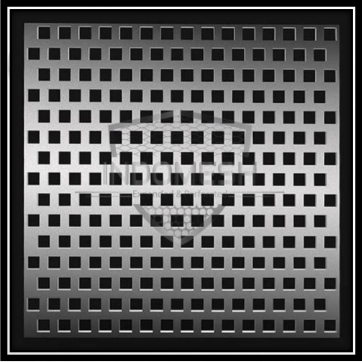

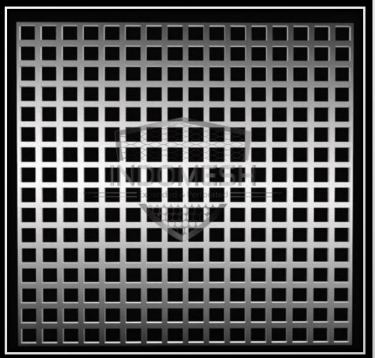

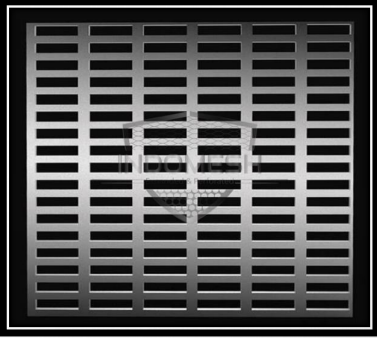

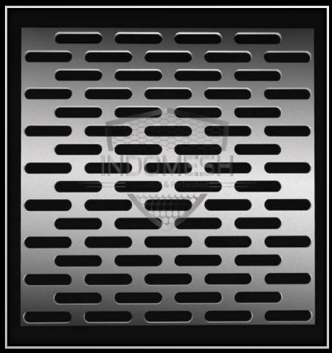

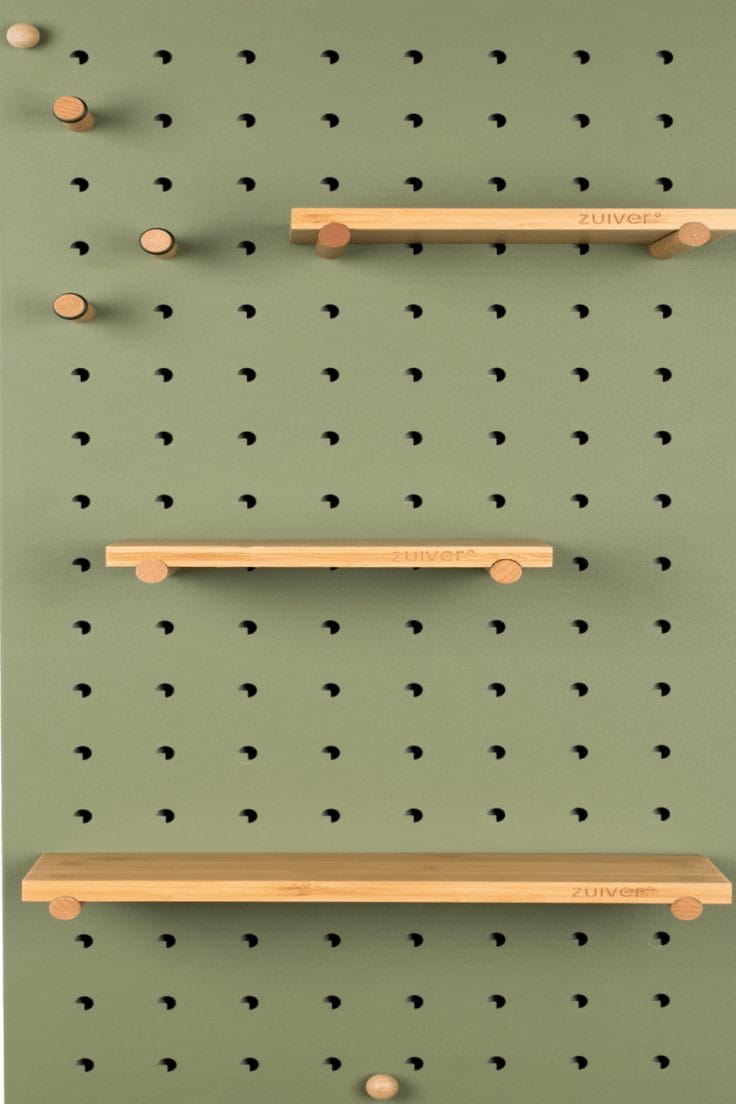

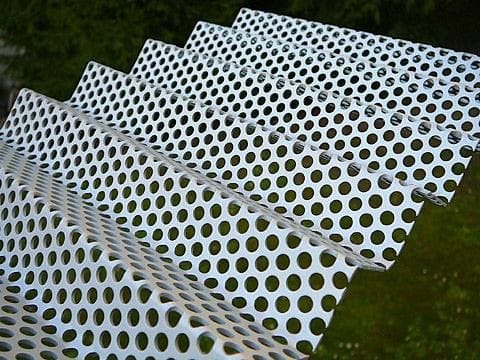

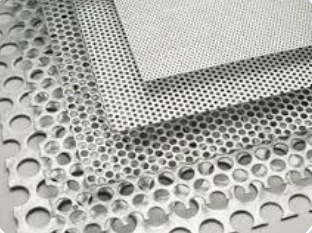

We Are a leading perforated sheet manufacturer with the widely famous brand name INDOMESH.

Established in the year 1984, Gupta Metal Mesh is the leading manufacturer and wholesaler of Perforated Sheet, Perforated Tray, Metal Mesh. Mentioned products are widely appreciated among customers for their unique attributes: precise fabrication, corrosion-resistant, perfect finish, tensile strength, longer service life and reliability. Our immersive knowledge and understanding in the domain have to aid us to become the undisputed leaders in providing the widely acclaimed products. Some of the factors that give us an edge over other market players are: High-tech manufacturing unit, Products in conformation with Specified Standards., Experienced professionals, Ethical business policies, Transparent dealings, Complete client satisfaction, Competitive pricing, Timely delivery.

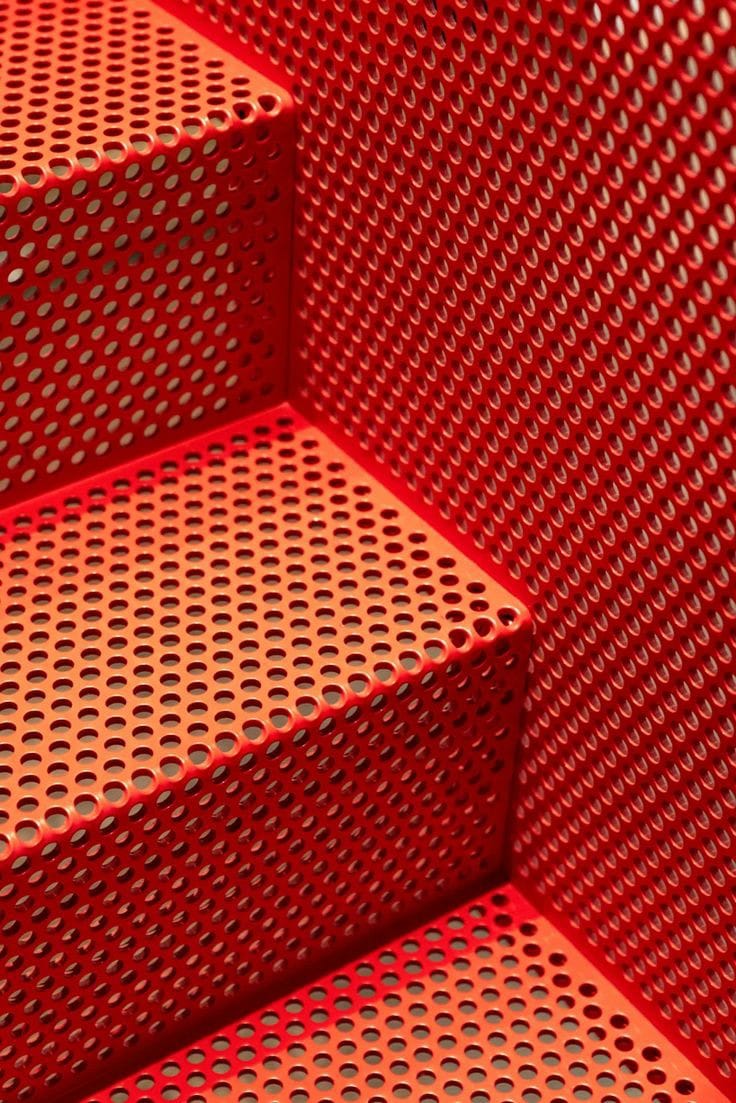

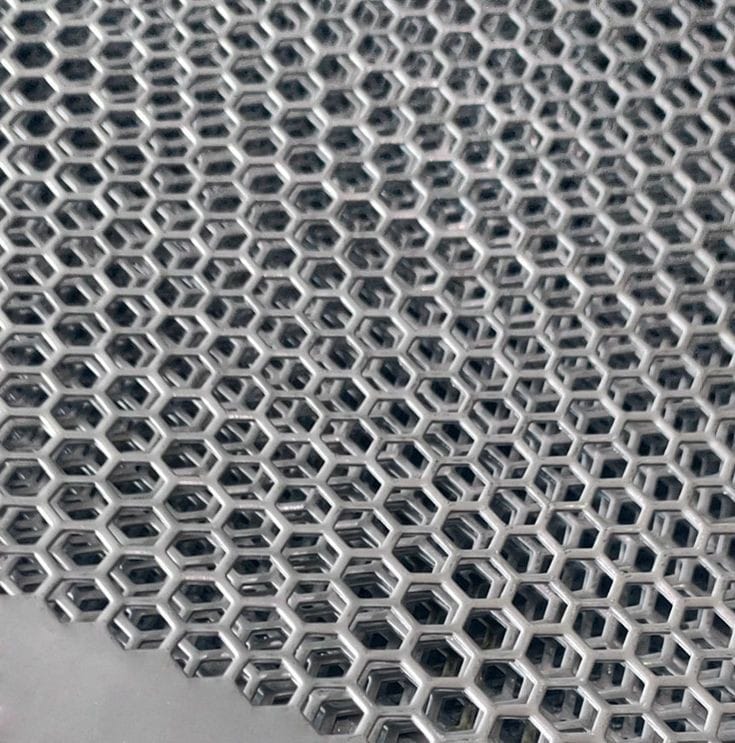

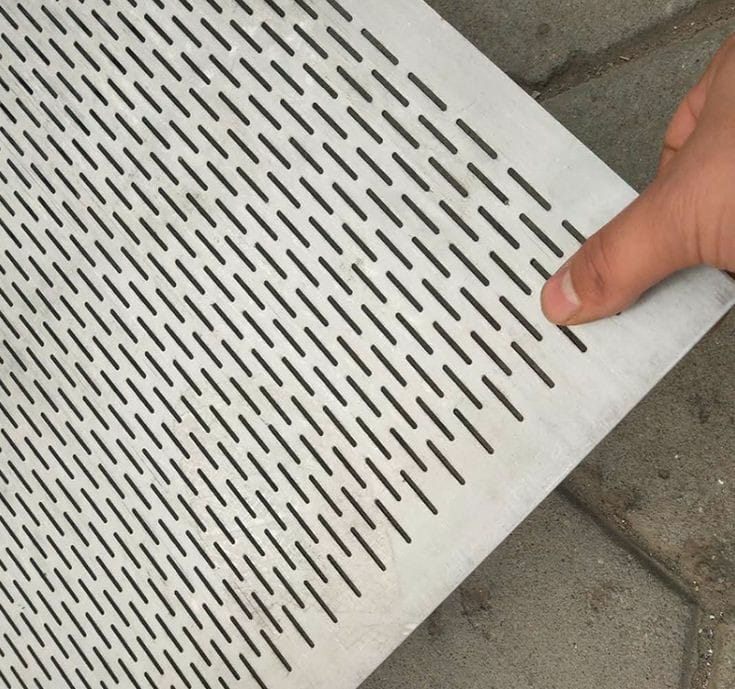

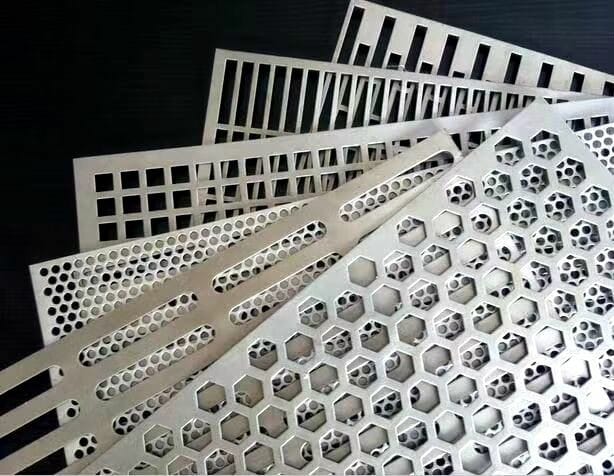

PERFORATED SHEET IN ALL METAL AND ALLOYS

.png)

Stainless Steel(304, 316, 316l)

.png)

Galvansied Sheet (HR,CR)

Brass & Copper

.png)

Mild Steel(HR, CR)

Aluminium SHEET, COIL

HDPE

USES

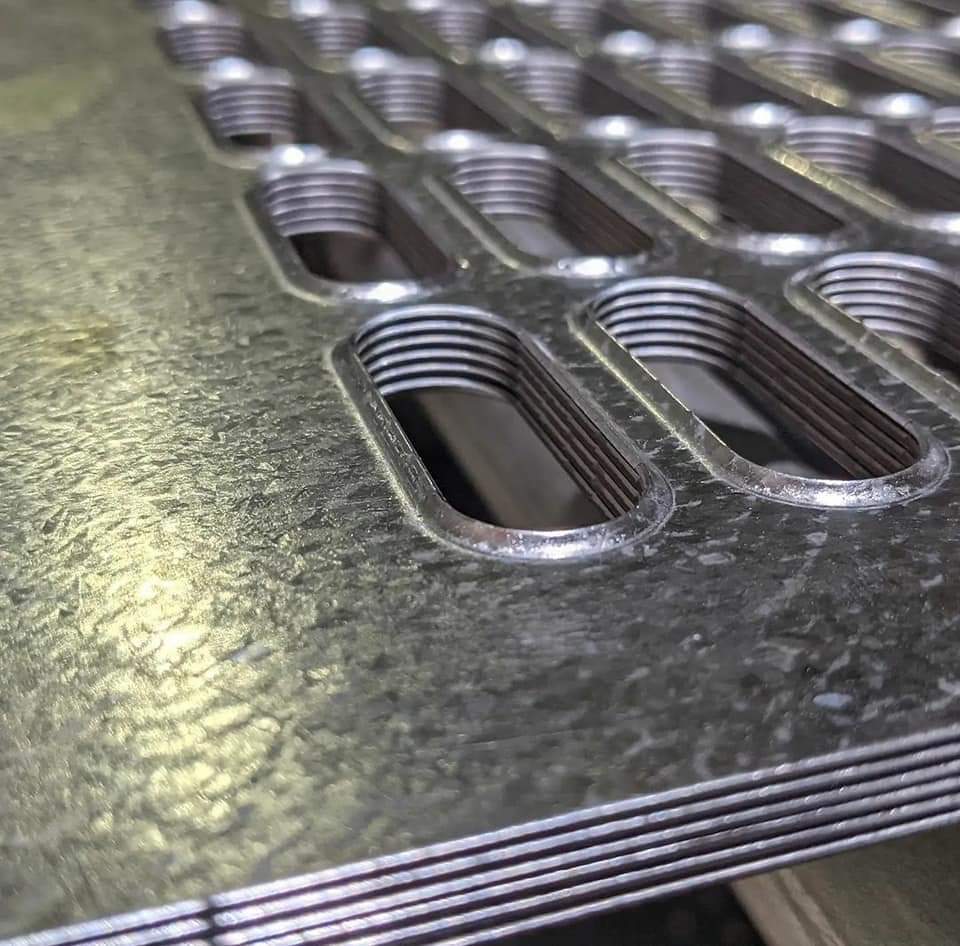

OTHER SERVICES

Cutting/Shearing

In order to suit the requirements of the intended application, a perforated sheet may be cut to a certain size.

Welding

According to the needs, welding is used to join two or more sheets to get the desired outcome. Various methods can be used to carry it out.

Grinding / Deburring

The method is used to lessen the sharp edges of perforated sheets and, if there are any burrs, to remove them from the back side. It is crucial to avoid compromising the end product's proper operation.

Bending (CNC Press Brakes)

A type of pressing tool identified as a press brake can bend sheet and plate material up to a height of 4 meters. By squeezing the work item between a corresponding punch and die, it creates bends that are predetermined

Straightener / Leveller

Based on the open area and the blank borders, the material naturally curves or bends during the perforating process. We have a facility here where the sheets can be straightened after perforation.

Powder Coating / Painting

We are able to supply finished goods of the highest caliber because to our powder coating setup and automated conveyer system, which is completed using a 7 tank technique.

PAYMENT

HDFC Bank

Name:-Gupta Metal Mesh

Account:-50200025190571

IFSC:-HDFC0000558

Copyright ©2023 All rights reserved | Designed and Developed by Waviator Solutions